Engineering Futures at Encocam: Apprenticeships, Careers, and Life‑Saving Innovation

26 January 2026Encocam is a global engineering and manufacturing business with a powerful purpose: to protect people, save lives, and enable innovation. We seek out opportunities – for development, collaboration, and innovation – and we believe the future of engineering depends on inspiring and supporting the next generation.

This article is written for young people, and also for parents, carers, teachers, and careers advisors who want clear, honest, and encouraging information about engineering careers. Whether you enjoy practical problem‑solving, cutting‑edge technology, or making a real‑world difference, engineering at Encocam can be a life‑changing pathway.

Manufacturing Technician Apprenticeships and Engineering Careers

What Is a Manufacturing Technician Apprenticeship?

A Manufacturing Technician apprenticeship is a hands‑on, paid route into engineering that combines: Practical, On‑the‑job experience, Formal technical education and mentoring from skilled engineers and technicians

Apprentices work alongside experienced professionals while gaining nationally recognised qualifications. It is a respected alternative to university – and for many, a faster and more practical route into a rewarding engineering career.

Why Choose an Apprenticeship in Engineering?

Engineering apprenticeships are ideal for people who:

- Enjoy learning by doing

- Like understanding how things work

- Want strong career prospects without student debt

- Are curious, practical and motivated

At Encocam, apprentices contribute to real projects from day one, helping manufacture advanced structures used across automotive, aerospace, defence, energy, and safety‑critical sectors.

Skills You Will Learn

As a Manufacturing Technician apprentice, you may develop skills in:

- Advanced manufacturing processes

- Composite materials and lightweight structures

- Precision assembly and quality control

- Reading engineering drawings and specifications

- Computer-aided manufacturing and inspection

- Health, safety and continuous improvement

You’ll also build valuable transferable skills such as teamwork, communication, problem‑solving, and time management – skills that employers actively seek.

Long‑Term Career Opportunities

An apprenticeship is not the end – it is the beginning.

Many apprentices progress into roles such as: Manufacturing or Production Engineer, Design or Development Engineer, Quality or Process Engineer, Project or Operations Manager, Engineering Team Leader.

With experience, further training, and ambition, apprentices can build long‑term, well‑paid careers with opportunities to work internationally and across multiple industries.

Supporting Parents, Carers, and Educators

Engineering apprenticeships are:

- Highly respected by employers

- Aligned with national skills needs

- Supported by structured training frameworks

- Proven pathways into stable, future-focused careers

For young people who thrive in practical and technical environments, an apprenticeship can be just as powerful – and often more suitable – than a traditional academic route.

Engineering That Saves Lives – Why It Matters

Engineering That Saves Lives – Why It Matters

Engineering is not just about machines and materials – it is about people.

At Encocam, engineering plays a vital role in life‑saving applications, from vehicle safety to sports injury reduction. Our work helps engineers, researchers, and safety organisations around the world design systems that protect lives.

Crash Test Dummies and Human Surrogates

Crash test dummies and advanced anthropomorphic test devices (ATDs) are essential for understanding how the human body responds to impact.

Engineered components within these systems help:

- Measure forces on the head, neck and torso

- Understand injury mechanisms

- Improve vehicle and transport safety standards

Encocam engineers contribute to the design and manufacture of precision energy‑absorbing structures used in these critical safety tools.

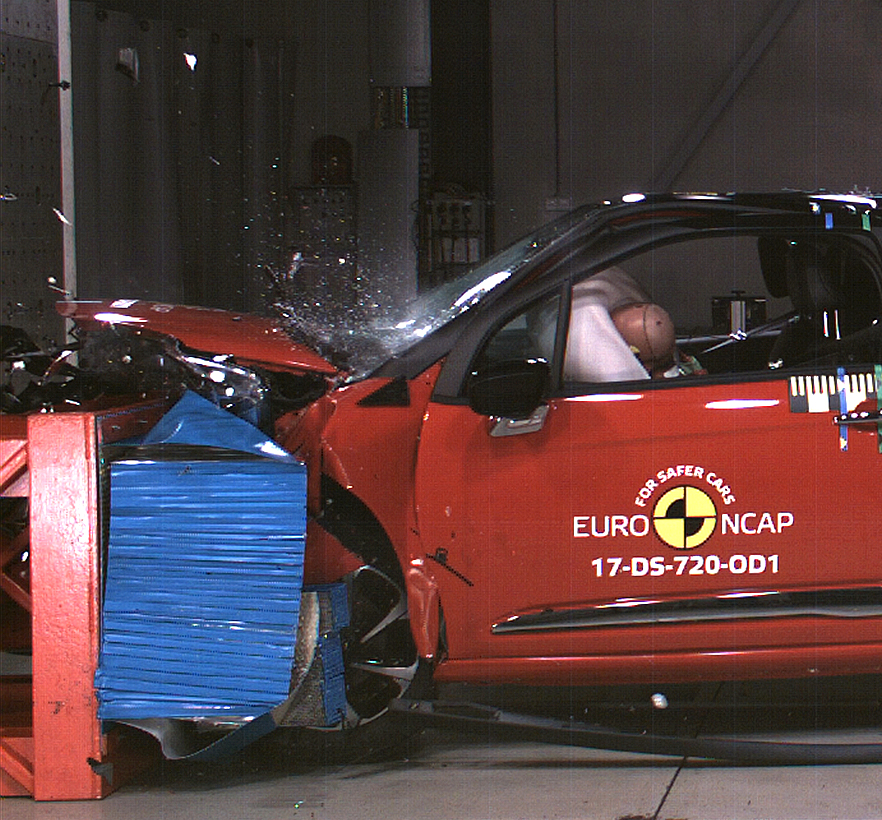

Energy Absorbers and Crash Protection

Energy absorbers are engineered structures designed to:

- Manage and dissipate impact forces

- Reduce peak loads on the human body

- Prevent catastrophic failure during collision

They are used in: Automotive and motorsport safety systems, crash test barriers, defence and aerospace applications.

This engineering directly reduced injury severity and saves lives every day.

Crash Test Barriers and Safety Systems

Crash test barriers must behave in a controlled, repeatable, and predictable way. Engineers carefully design these systems to simulate real‑world accidents and generate accurate data.

This allows manufacturers and regulators to:

- Improve vehicle designs

- Set higher safety standards

- Protect drivers, passengers and pedestrians

FEA Modelling: Engineering Before It Happens

Finite Element Analysis (FEA) allows engineers to simulate crashes, impacts, and stresses before physical testing begins. Using advanced modelling techniques, engineers can:

- Predict structural behaviour

- Optimise designs for safety and efficiency

- Reduce development time and cost

- Improve reliability and performance

FEA is a key skill for modern engineers and a powerful example of how digital engineering supports life‑saving innovation.

Headforms and Helmet Safety

Headforms are precision‑engineered tools used to assess helmet performance and reduce sports‑related head injuries. They are essential in:

- Cycling

- Motorsport

- Equestrian Safety

- Reducing concussion risk

- Improving protective equipment standards

Engineering better headforms means better helmets, safer sports, and fewer life‑changing injuries.

Inspiring the Next Generation

For young people considering engineering, this work offers something rare:

A career where technical skill meets real human impact.

Engineering at Encocam is about curiosity, responsibility, and purpose. It is about using innovation to solve problems that truly matter.

Manufacturing Technician Apprenticeships (FAQs)

In line with national careers guidance, entry requirements focus on a young person’s aptitude, motivation, and potential. GCSEs (or equivalents) in maths, science, or technology-related subjects are often beneficial, but employers also value practical skills, problem-solving ability, and a positive attitude to learning.

Yes. Apprenticeships are paid employment with structured training, allowing young people to earn a salary while gaining recognised qualifications and workplace experience.

Apprenticeships are designed as progression pathways, not end points. They can lead to higher-level qualifications, professional engineering roles, leadership positions, and in some cases degree-level study.

Apprentices receive off-the-job training, workplace mentoring, and regular progress reviews. This aligns with best practice in careers education by supporting both technical development and personal growth.

Yes. Apprenticeships are particularly well suited to learners who thrive in hands-on, applied learning environments and want to see the real-world impact of their skills.

Engineering and Life-Saving Applications (FAQs)

Engineering contributes directly to public safety, health, and wellbeing by improving transport safety, protective equipment, and injury prevention systems.

They enable engineers to understand how the human body responds to impact, supporting evidence-based design decisions and improved safety standards.

Finite Element Analysis (FEA) is a digital engineering tool used across modern industries. It supports analytical thinking, problem-solving, and innovation – skills highlighted in national careers frameworks.

Engineering-led testing using headforms helps reduce the risk of concussion and serious injury, directly supporting safer participation in sport and physical activity.

Yes. With appropriate supervision and training, early-career engineers regularly contribute to real, safety-critical projects, gaining valuable experience while delivering positive societal impact.