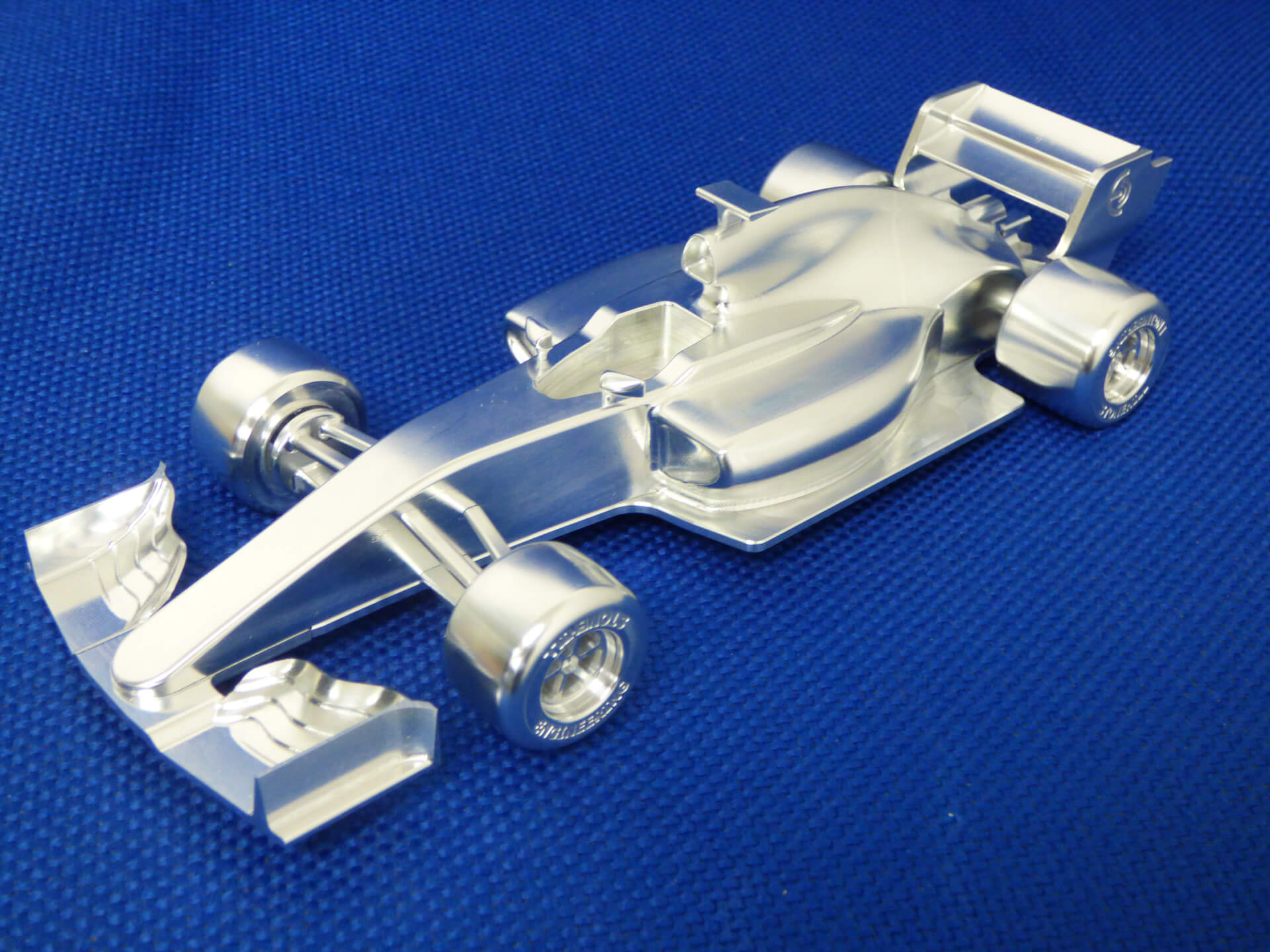

Stonehill Engineering is a precision engineering company offering design and development, CNC and conventional machining, milling and turning, surface grinding and welding and custom specialised parts for our Anthropomorphic Test Devices. Quality customer service is one of our key commitments, we believe in continuous improvement and adhere to stringent quality checks at all stages of the production process.

Design and Development: Our dedicated team offer a comprehensive service from concept through to production. This includes initial consultation, 2D drawing of components and 3D model production for manufacture.

CNC Machining/Conventional Machining: In all areas including milling and turning – providing total production needs. We have three 5 Axis machines.

Spark Eroders and Surface Grinding: We are able to offer these services to our customers.

Welding and Fabrication: Sheet metal work and MIG and TIG welding can be completed using a variety of metals.

Toolmaking: We offer a complete component production process to turn concepts into 3D models or parts for production. This, in turn, can be followed on by a prototyping or prototype moulding service. We aim to be a one-stop tooling package provider.

Our continued investment in the latest plant technology and machinery has been a determining factor in our steady growth, supported by a commitment to achieving the highest standard of quality, both during and after production. Stonehill Engineering has an impressive array of equipment, including a 5 Axis machine centre, enabling the delivery of complex products with incredible accuracy.

Bespoke and Custom Parts: Our skilled in-house design department creates, designs and alters bespoke components for clients. 3D CAD technology, compatible with all the latest process-flow software, is used to compose accurate engineering drawings. These can be developed to produce computer visual models and solid models. The end result is a fully bespoke and accurate manufacturing process from start to finish.

Visit the Stonehill Engineering website to learn more about Precision Engineering.