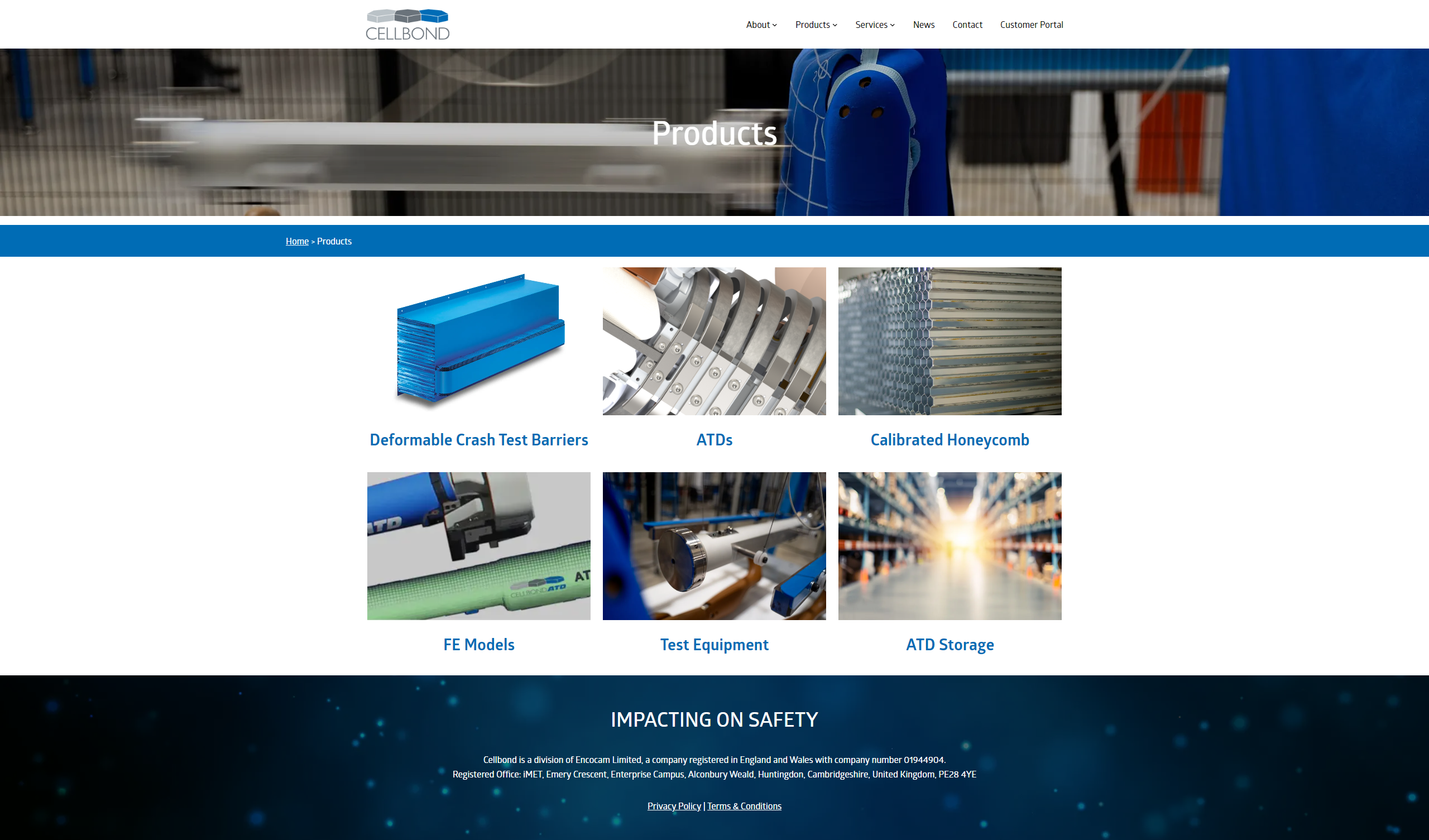

Encocam’s specialist passive safety business unit, Cellbond, has launched a new website showcasing a wide range of products and services that are used in the testing phase of new vehicle design and manufacture. Cellbond designs, develops and manufactures sophisticated biofidelic crash test dummies, leg form impactors, head impactors and deformable aluminium crash test barriers, all of which are used in crash test scenarios around the world. Cellbond is a proud holder of the Queen’s Award for Enterprise: International Trade, and the team work with global N-CAP organisations, automotive manufacturers, and government agencies to reduce the death and injury of vehicle occupants and pedestrians.

Encocam is an award-winning global business specialising in engineering and manufacturing.

We combine innovative design with traditional and cutting-edge engineering processes to deliver a wide range of products which are manufactured in Huntingdon and despatched to our global customer base. In return for your hard work and commitment we offer excellent career and personal development opportunities and place great value on our apprentices across the business.

We select candidates who show that they have the determination and desire to succeed in their chosen field. Your apprenticeship experience with Encocam will give you:

- Hands on experience within your chosen sector

- The means to earn as you learn

- Industry recognised qualifications from levels 2-6

- Improved future prospects

- Ongoing and personalised support from your team and other colleagues

- Personal and career development opportunities

For more information please contact Kim Smith,

Recruitment Co-ordinator, at

kim.smith@encocam.com